Aim: Real-time monitoring of energy plant components.

Technologies: Fiber Bragg Grating

Description: The major failures in an energy production plant are related to heat exchangers placed in highly hostile environments and at high temperatures, causing frequent stops for repair. In order to perform a predictive maintenance of the components, the plant can exploit the information acquired by a real time FBG-based monitoring system capable of accurately measuring hundreds of temperature points placed over the whole surface of the components. The solution provided by INFIBRA TECHNOLOGIES is based on the simultaneous reading by our FBG.HUB UNIT of several HT-Flex500 probes welded to the skin of the components to be monitored equipped with dozens of sensors each. These components are usually located in large confined areas with a high temperature and oxidative degree: for that reason, the solution involves all-metal cables resistant to this environment.

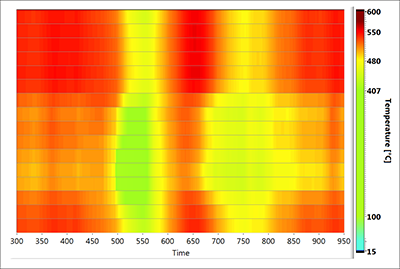

The fibers, outside the confined space, are then connected via multi-fiber cables for acquisition, processing and communication of the measurements to DCS/SCADA system. INFIBRA TECHNOLOGIES has developed a specific monitoring system, suitable for monitoring and processing thousands of temperature sensors, download our reference for more information. An example of temperature mapping over time, obtained by the system, is reported in the graph.