FBG Sensors

INFIBRA TECHNOLOGIES can offer a range of FBG-based different sensors as well as supplies custom solution starting from single FBGs and arrays of FBGs. A short list of standard solutions is reported below, click on the picture in a selected tab to read the specifications.

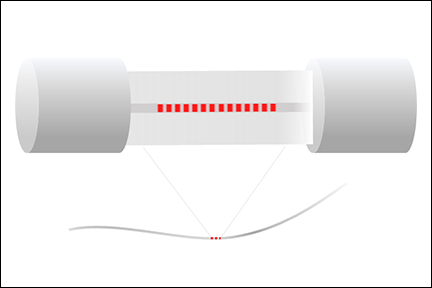

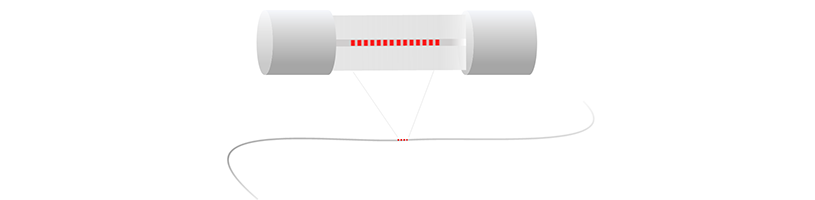

Single FBG can be used for sensing temperature and strain as well as for many physical and chemical parameters if properly packaged. Several coatings (acrylate, polyimide or metallic) and manufacturing parameters (length, bandwidth, peak reflecticvity) are available for industrial applications, even in harsh environments with ATEX and high temperatures requirements.

Single FBG can be used for sensing temperature and strain as well as for many physical and chemical parameters if properly packaged. Several coatings (acrylate, polyimide or metallic) and manufacturing parameters (length, bandwidth, peak reflecticvity) are available for industrial applications, even in harsh environments with ATEX and high temperatures requirements.Single Fiber Bragg Grating

- Civil engineering

- Transportation

- Chemical Processes

- Power

- Oil&Gas

- Automotive & Aerospace

- Medical & Robotics

- Telecommunications

- Reasearch & Development

FBG specifications:

| FBG Wavelength (CWL) | 1.500 ÷ 1.600 nm (other on request) |

| FBG Wavelength tolerance (CWLT) | ± 0,5 nm (other on request) |

| FBG Bandwidth (FWHM) | 0,1 nm to 1 nm (other on request) |

| FBG Reflectivity Peak (R) | Up to 99 % (50% typical) |

| Side Lobe Suppression Ratio (SLSR) | > 15dB (other on request) |

| FBG Length (L) | 1 ÷ 12 mm (other on request) |

| Fiber Type | Standard single-mode, Bend insensitive, Pure core silica, (others on request) |

| Fiber coating | Acrylate (up to 80°C), High Temperature Acrylate (up to 150°C), Polyimide (up to 250°C, short term 400°C), Metal coating on request (up to 700°C) |

| Fiber pigtail length | 1 m both side (other on request) |

| Optical connector | FC/APC (other on request) |

| Packaging options | Tubing (e.g. polymeric, stainless steel, PEEK, PTFE), extra buffer ruggedization (other on request) |

Download Datasheet

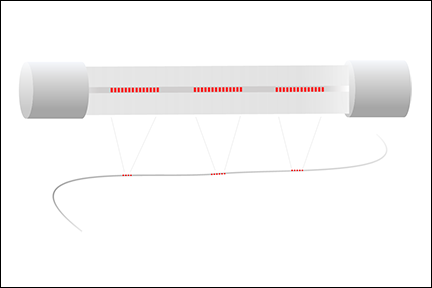

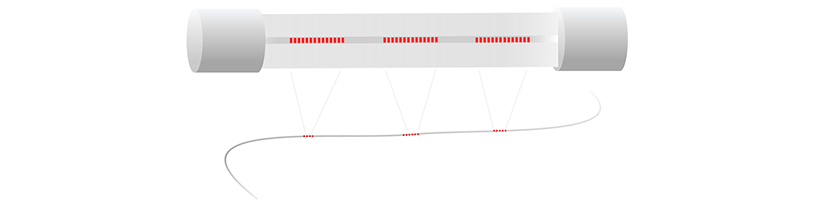

Array of FBGs can be offered in a wide range of optical specifications and material options to meet all customer requirements. It is possible to write dozens of FBG in a single optical fiber. Custom FBG spacing, several coatings and manufacturing parameters (length, bandwidth, peak reflecticvity) are available for quasi-distributed long-term sensing applications.

Array of FBGs can be offered in a wide range of optical specifications and material options to meet all customer requirements. It is possible to write dozens of FBG in a single optical fiber. Custom FBG spacing, several coatings and manufacturing parameters (length, bandwidth, peak reflecticvity) are available for quasi-distributed long-term sensing applications.Single Fiber with Array of Bragg Gratings

- Civil engineering

- Transportation

- Chemical Processes

- Power

- Oil&Gas

- Automotive & Aerospace

- Medical & Robotics

- Telecommunications

- Reasearch & Development

Array of FBGs specifications:

| Number of FBGs per array | Up to 50 (higher on request) |

| FBGs Spacing | >15 mm (other on request) |

| FBG Wavelength (CWL) | 1.500 ÷ 1.600 nm (other on request) |

| FBG Wavelength tolerance (CWLT) | ± 0,5 nm (other on request) |

| FBG Bandwidth (FWHM) | 0,1 nm to 1 nm (other on request) |

| FBG Reflectivity Peak (R) | Up to 99 % (50% typical) |

| Side Lobe Suppression Ratio (SLSR) | > 15dB (other on request) |

| FBG Length (L) | 1 ÷ 12 mm (other on request) |

| Fiber Type | Standard single-mode, Bend insensitive, Pure core silica, (others on request) |

| Fiber coating | Acrylate (up to 80°C), High Temperature Acrylate (up to 150°C), Polyimide (up to 250°C, short term 400°C), Metal coating on request (up to 700°C) |

| Fiber pigtail length | 1 m both side (other on request) |

| Optical connector | FC/APC (other on request) |

| Packaging options | Tubing (e.g. polymeric, stainless steel, PEEK, PTFE), extra buffer ruggedization (other on request) |

Download Datasheet

HT-Tube500 is a in-well temperature sensor for harsh environments with operating temperatures up to 500 °C (600 °C R&D). Its stainless steel rigid metallic tube (5 mm typical outer diameter) holds a cascade of FBG sensors, which enables the insertion temperature profile over the thickness of components.

HT-Tube500 is a in-well temperature sensor for harsh environments with operating temperatures up to 500 °C (600 °C R&D). Its stainless steel rigid metallic tube (5 mm typical outer diameter) holds a cascade of FBG sensors, which enables the insertion temperature profile over the thickness of components.Rugged In-Well High Temperature FBG Sensor

- Machine Condition Monitoring

- Power Plants Transformers

- Chemical Processes

- Conveyor Systems

- High Temperature Environments

Physical specifications:

| Sensor Construction | Rigid Loose Tube |

| Dimension (φ x L) | Tube diameter and sensor length to suit application |

| Package material | Stainless steel AISI 304 or other options |

| Fixing method | Swagelok , Glue |

Optical specifications:

| Fiber Type | Single-mode SMF-28 9/125 μm |

| FBG Wavelength (CWL) | 1.460 ÷ 1.620 nm |

| FBG Bandwidth (FWHM) | 0,25 nm (typical) |

| FBG Peak Reflectivity (R) | > 50 % |

| Side Lobe Suppression Ratio (SLSR) | > 15dB |

| Sensors Spacing (D) | >7 mm (Customizable) |

| Sensors Number | Custom to suit application |

| Measurement Range | -50 to 500 °C (600 °C R&D) |

| Sensor Resolution | 0,1 °C (depending on FBG interrogator) |

| Sensor Accuracy | 0,5 °C (depending on FBG interrogator) |

| Cable Length and Connector | to suit application |

Download Datasheet

HT-Flex500 is a flexible temperature sensor for harsh environments with operating temperatures up to 500 °C (600 °C R&D). Its stainless steel flexible capillary tube (1.2 mm typical diameter) holds a cascade of FBG sensors, which enables both surface and embedded installations, even within extremely small wells.

HT-Flex500 is a flexible temperature sensor for harsh environments with operating temperatures up to 500 °C (600 °C R&D). Its stainless steel flexible capillary tube (1.2 mm typical diameter) holds a cascade of FBG sensors, which enables both surface and embedded installations, even within extremely small wells.Flexible High Temperature FBG Sensor

- Machine Condition Monitoring

- Power Plants Transformers

- Chemical Processes

- Conveyor Systems

- High Temperature Environments

Physical specifications:

| Sensor Construction | Capillary Loose Tube |

| Dimension (φ x L) | 1.2 mm x L (Sensor Length to suit application) |

| Flexibility | Down to 300 mm diameter |

| Package material | Stainless steel AISI 304 or other options |

Optical specifications:

| Fiber Type | Single-mode SMF-28 9/125 μm |

| FBG Wavelength (CWL) | 1.460 ÷ 1.620 nm |

| FBG Bandwidth (FWHM) | 0,25 nm (typical) |

| FBG Peak Reflectivity (R) | > 50 % |

| Side Lobe Suppression Ratio (SLSR) | > 15dB |

| Sensors Spacing (D) | > 7 mm (Customizable) |

| Sensors Number | Custom to suit application |

| Measurement Range | -50 to 500 °C (600 °C R&D) |

| Sensor Resolution | 0,1 °C (depending on FBG interrogator) |

| Sensor Accuracy | 0,5 °C (depending on FBG interrogator) |

| Cable Length and Connector | to suit application |

Download Datasheet

FTT-01 is a customizable fiber-optic-based force and mechanical moment sensor designed for precision load monitoring in bolted joints and structural interfaces. Based on Fiber Bragg Grating (FBG) technology, it is engineered to function in extreme temperature environments and wide dynamic range.

FTT-01 is a customizable fiber-optic-based force and mechanical moment sensor designed for precision load monitoring in bolted joints and structural interfaces. Based on Fiber Bragg Grating (FBG) technology, it is engineered to function in extreme temperature environments and wide dynamic range.Smart Washer for Bolted Joints

- Structural load monitoring

- Aerospace and automotive testing

- Industrial machinery diagnostics

- Smart bolted connections

- Harsh environment force sensing

Physical specifications:

| Form factor | Customizable (Inner hole, shape) |

| Minimum Outer Diameter | 25 mm (<25 mm R&D) |

| Minimum Thickness | 4 mm (<4 mm R&D) |

| Package material | Application customizabled (e.g. aluminum. stainless steel, titanium) |

| Operating Temperature | -80 °C to +250 °C |

| IP Grade | up to IP68 |

Measurement specifications:

| Measurement Capacities | > 30 kN |

| Sensor Technology | Multiple Fiber Bragg Gratings (FBGs) |

| Resolution | Up to 0.05% of full scale (application dependent) |

| Sampling Rate | Depending on used FBG interrogator |

| FBG Central Wavelength | Within the range 1460 ÷ 1620 nm |

| FBG Bandwidth | 1 nm (typical) |

| Temperature Compensation | Reference Temperature FBGs (optional) |

Download Datasheet

Video Demo Youtube Channel